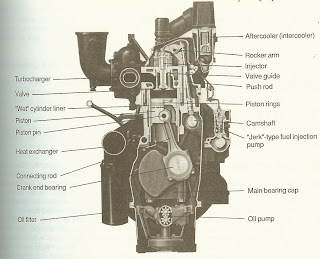

The core of marine diesel engines are the combustion chambers. In each chamber, a piston goes goes up and down based on the combustion of diesel fuel. A connecting rod transfers the motion of the piston to the crankshaft. The crankshaft converts the up and down motion to useful rotation. At its most basic level, the idea is simple, but to make an engine work in the real world, systems must inject fuel, lubricate the pistons, and dissipate excess heat. These three systems are known as the fuel, lubrication, and cooling systems.

Fuel

A tank stores diesel fuel. A fuel injection pump sprays diesel into each chamber. This pump is the most expensive part on a diesel engine. A governor controls the quantity of fuel. The piston compresses the diesel which naturally ignites without stimulus from a spark plug like in a gasoline engine. Valves controlled by the camshaft open and close to let out the exhaust fumes and in fresh air. Ninety percent of engine problems are due to contaminated fuel. A fuel filter is essential to keep the engine running well.

Lubrication

In the bottom of the engine is an oil sump. An oil pump circulates the oil through openings in the engine block called the oil galleries. The oil sprays out throughout the block onto the pistons and shafts to lubricate their motion. Then, the oil seeps down again into the sump in the bottom of the block. An oil filter is key to keep the oil circulating.

Cooling

There are two types of cooling systems: raw water and fresh water. In a raw water system, saltwater rushes throughout the jackets of the engine absorbing heat, returns overboard to the body of water. Problems with directly using raw water include silt, corrosion, and scale. In a fresh water system, coolant circulates throughout the jackets of the engine. Then the coolant flows through small diameter pipes in a heat exchanger. The head exchanger is full of saltwater which flows in and out from the immersed body of water. The coolant takes the heat from the engine and dissipates that heat into the saltwater in the heat exchanger. That saltwater bath water circulates overboard. A thermostat controls the preferred temperature of the engine. Raw water engines run at 140-160 degrees Fahrenheit. Fresh water engines should run at 185 degree Fahrenheit.

Conclusion

The engine is based on pistons going up and down in combustion chambers. Fuel, lubrication, and cooling systems manage this action. The italicized terms above are important parts of a marine diesel engine. Beyond the engine are the transmission, shaft, propeller, and steering which together eventually work to propel a boat.

Fuel

A tank stores diesel fuel. A fuel injection pump sprays diesel into each chamber. This pump is the most expensive part on a diesel engine. A governor controls the quantity of fuel. The piston compresses the diesel which naturally ignites without stimulus from a spark plug like in a gasoline engine. Valves controlled by the camshaft open and close to let out the exhaust fumes and in fresh air. Ninety percent of engine problems are due to contaminated fuel. A fuel filter is essential to keep the engine running well.

Oil Cooler (Marine Diesel Engines)

In the bottom of the engine is an oil sump. An oil pump circulates the oil through openings in the engine block called the oil galleries. The oil sprays out throughout the block onto the pistons and shafts to lubricate their motion. Then, the oil seeps down again into the sump in the bottom of the block. An oil filter is key to keep the oil circulating.

Cooling

There are two types of cooling systems: raw water and fresh water. In a raw water system, saltwater rushes throughout the jackets of the engine absorbing heat, returns overboard to the body of water. Problems with directly using raw water include silt, corrosion, and scale. In a fresh water system, coolant circulates throughout the jackets of the engine. Then the coolant flows through small diameter pipes in a heat exchanger. The head exchanger is full of saltwater which flows in and out from the immersed body of water. The coolant takes the heat from the engine and dissipates that heat into the saltwater in the heat exchanger. That saltwater bath water circulates overboard. A thermostat controls the preferred temperature of the engine. Raw water engines run at 140-160 degrees Fahrenheit. Fresh water engines should run at 185 degree Fahrenheit.

Conclusion

The engine is based on pistons going up and down in combustion chambers. Fuel, lubrication, and cooling systems manage this action. The italicized terms above are important parts of a marine diesel engine. Beyond the engine are the transmission, shaft, propeller, and steering which together eventually work to propel a boat.

No comments:

Post a Comment