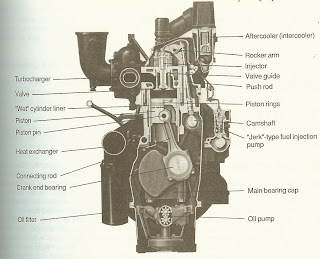

A four-stroke engine, also known as four-cycle, is an internal combustion engine in which the piston completes four separate strokes—intake, compression, power, and exhaust—during two separate revolutions of the engine's crankshaft, and one single thermodynamic cycle.

There are two common types of engines, which are closely related to each other but have major differences in their design and behavior. The earliest of these to be developed is the Otto cycle engine which was developed in 1876 by Nikolaus August Otto in Cologne, Germany[1]. This engine is most often referred to as a petrol engine or gasoline engine, after the fuel that powers it.[2] The second type of four-cycle engine is the Diesel engine developed in 1893 by Rudolph Diesel, also of Germany. Diesel created his engine to maximize efficiency which was lacking in the Otto engine. There are several major differences between the Otto cycle engine and the four cycle diesel engine. The diesel engine is made in both a two-cycle and a four-cycle version. Ironically Otto's company Deutz AG produces primarily diesel engines in the modern era.

The Otto cycle is named after the 1876 engine of Nikolaus A. Otto, who built a successful four-cycle engine which was based on the work of Jean Joseph Etienne Lenoir.[1] It was the third engine type that Otto developed. It used a sliding flame gateway for ignition of its fuel which was a mixture of illuminating gas and air. After 1884 Otto also developed the magneto allowing the use of an electrical spark for ignition, which had been unreliable on the Lenoir engine.

Today, the internal combustion engine (ICE) is used in motorcycles, automobiles, boats, trucks, aircraft, ships, heavy duty machinery, and in its original intended use as stationary power both for kinetic and electrical power generation. Diesel engines are found in virtually all heavy duty applications such as trucks, ships, locomotives, power generation, and stationary power. Many of these diesel engine are two cycle with power ratings up to 105,000 hp (78,000 kW).

The four cycles refer to intake, compression, combustion (power), and exhaust cycles that occur during two crankshaft rotations per power cycle of the four cycle engines. The cycle begins at Top Dead Centre (TDC), when the piston is farthest away from the axis of the crankshaft. A cycle refers to the full travel of the piston from Top Dead Centre (TDC) to Bottom Dead Centre (BDC). (See Dead centre.)

There are two common types of engines, which are closely related to each other but have major differences in their design and behavior. The earliest of these to be developed is the Otto cycle engine which was developed in 1876 by Nikolaus August Otto in Cologne, Germany[1]. This engine is most often referred to as a petrol engine or gasoline engine, after the fuel that powers it.[2] The second type of four-cycle engine is the Diesel engine developed in 1893 by Rudolph Diesel, also of Germany. Diesel created his engine to maximize efficiency which was lacking in the Otto engine. There are several major differences between the Otto cycle engine and the four cycle diesel engine. The diesel engine is made in both a two-cycle and a four-cycle version. Ironically Otto's company Deutz AG produces primarily diesel engines in the modern era.

The Otto cycle is named after the 1876 engine of Nikolaus A. Otto, who built a successful four-cycle engine which was based on the work of Jean Joseph Etienne Lenoir.[1] It was the third engine type that Otto developed. It used a sliding flame gateway for ignition of its fuel which was a mixture of illuminating gas and air. After 1884 Otto also developed the magneto allowing the use of an electrical spark for ignition, which had been unreliable on the Lenoir engine.

Today, the internal combustion engine (ICE) is used in motorcycles, automobiles, boats, trucks, aircraft, ships, heavy duty machinery, and in its original intended use as stationary power both for kinetic and electrical power generation. Diesel engines are found in virtually all heavy duty applications such as trucks, ships, locomotives, power generation, and stationary power. Many of these diesel engine are two cycle with power ratings up to 105,000 hp (78,000 kW).

The four cycles refer to intake, compression, combustion (power), and exhaust cycles that occur during two crankshaft rotations per power cycle of the four cycle engines. The cycle begins at Top Dead Centre (TDC), when the piston is farthest away from the axis of the crankshaft. A cycle refers to the full travel of the piston from Top Dead Centre (TDC) to Bottom Dead Centre (BDC). (See Dead centre.)

- INTAKE stroke: on the intake or induction stroke of the piston, the piston descends from the top of the cylinder to the bottom of the cylinder, reducing the pressure inside the cylinder. A mixture of fuel and air, or just air in a diesel engine, is forced by atmospheric (or greater) pressure into the cylinder through the intake port. The intake valve(s) then close. The volume of air/fuel mixture that is drawn into the cylinder, relative to the volume of the cylinder is called, the volumetric efficiency of the engine.

- COMPRESSION stroke: with both intake and exhaust valves closed, the piston returns to the top of the cylinder compressing the air, or fuel-air mixture into the combustion chamber of the cylinder head.

- POWER stroke: this is the start of the second revolution of the engine. While the piston is close to Top Dead Center, the compressed air–fuel mixture in a gasoline engine is ignited, usually by a spark plug, or fuel is injected into the diesel engine, which ignites due to the heat generated in the air during the compression stroke. The resulting massive pressure from the combustion of the compressed fuel-air mixture forces the piston back down toward bottom dead centre.

- EXHAUST stroke: during the exhaust stroke, the piston once again returns to top dead center while the exhaust valve is open. This action evacuates the burnt products of combustion from the cylinder by expelling the spent fuel-air mixture out through the exhaust valve(s).